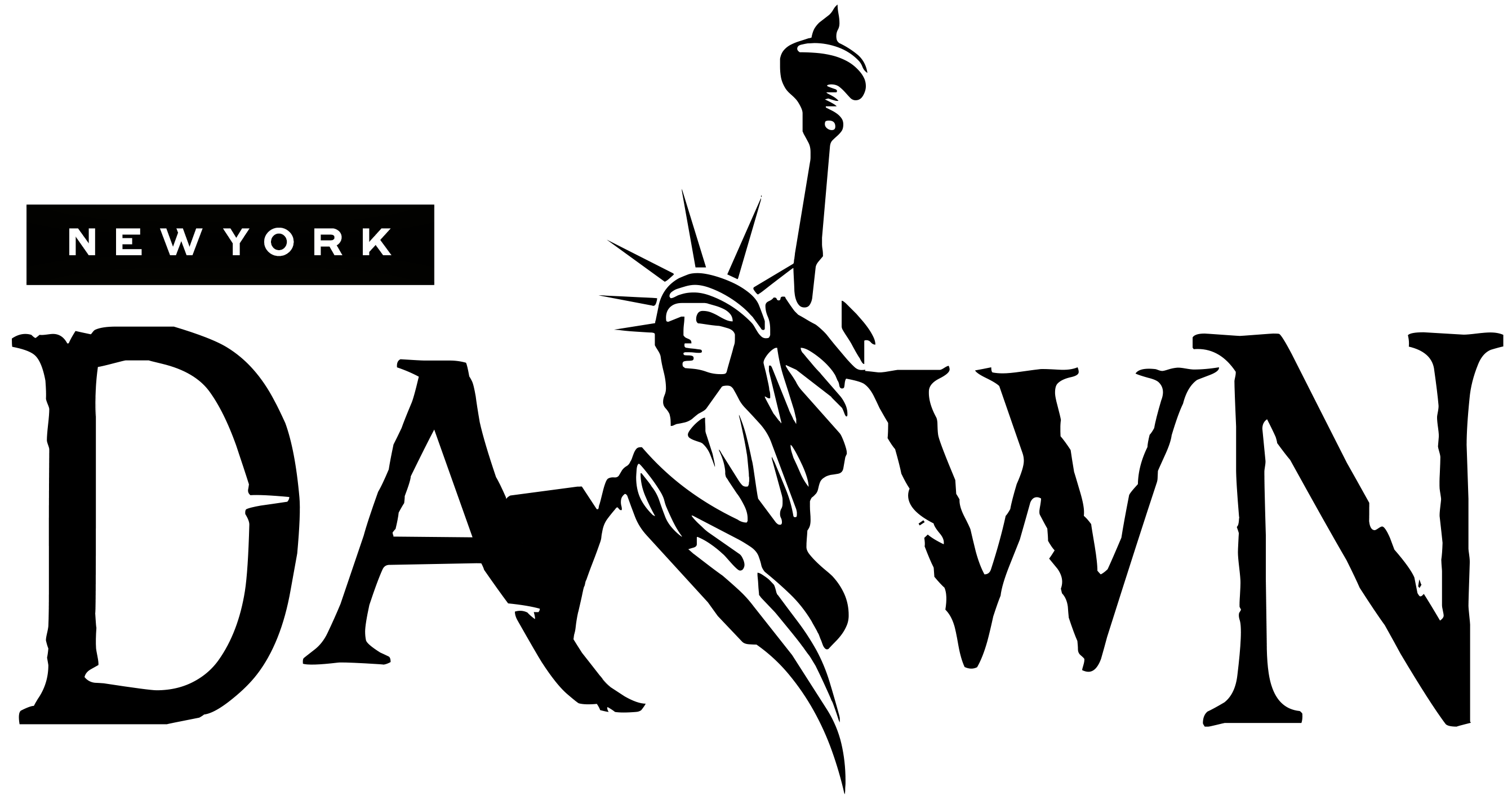

An instance of a contact lens with the Waterloo analysis staff’s hydrogel “stitched” on it. The hydrogel is 3D-printed all through the periphery of the lens. Credit score: College of Waterloo

The following time you might want to take a prescription drug, taking it is likely to be as straightforward as placing on a contact lens, because of a brand new discovery made by College of Waterloo researchers.

The staff of researchers—which spans Waterloo’s Division of Chemistry and its Faculty of Optometry and Imaginative and prescient Science—created a brand new kind of hydrogel that may ship medication to sufferers with varied eye points when 3D printed onto a contact lens.

The paper, “Injectable and 3D Extrusion Printable Hydrophilic Silicone-Based Hydrogels for Controlled Ocular Delivery of Ophthalmic Drugs,” was revealed in ACS Utilized Bio Supplies.

The hydrogel, a kind of gel that may retain important volumes of water, is silicone-based and may also help management the quantity of treatment an individual would want, constantly delivering it so long as the contact lens is worn.

Utilizing these hydrogel-loaded contact lenses may assist physicians scale back ache and the variety of occasions the affected person has to use the drug, because the treatment is delivered throughout regular contact lens put on.

Although silicone may be difficult to 3D print, this new hydrogel is totally different. It makes use of a particular kind of silicone that simply attracts water and is curable with UV gentle. After curing, the gel is each versatile and sturdy sufficient to maintain its form after being stretched and compressed.

“Once we knew the hydrogel had good strength and flexibility, we decided to test its ability to hold and release drugs by using amoxicillin, a commonly prescribed antibiotic for ailments related to the eye,” stated Shirley Tang, a Waterloo professor within the Division of Chemistry and Affiliate Dean, Analysis within the School of Science.

The researchers discovered that the hydrogel’s macro-porous construction helped regulate the discharge of amoxicillin over time throughout lab testing. The hydrogels have been additionally discovered to be injectable and extrusion printable, which means they might simply be printed onto a contact lens.

“This concept is much more efficient and easier to comply with than using eye drops, which are often difficult to insert for patients and need frequent administration over the day,” stated Lyndon Jones, a Waterloo professor within the Faculty of Optometry and Imaginative and prescient Science and director of the Middle for Ocular Analysis & Training.

The analysis staff additionally wished to check the shelf stability of the hydrogel materials and located that the drug encapsulation was exceptionally secure after a month.

“After being encapsulated in the gel and stored for a month, the amoxicillin was found to have negligible changes,” stated Sayan Ganguly, a post-doctoral researcher within the Division of Chemistry. “Our results showed that this hydrogel is safe for human eyes and can be effectively used in diverse biomedical applications.”

With their just lately filed patent, the researchers goal to broaden the usage of contact lenses for treating eye sicknesses.

Extra data:

Sayan Ganguly et al, Injectable and 3D Extrusion Printable Hydrophilic Silicone-Primarily based Hydrogels for Managed Ocular Supply of Ophthalmic Medicine, ACS Utilized Bio Supplies (2024). DOI: 10.1021/acsabm.4c00901

Offered by

College of Waterloo

Quotation:

3D-printed hydrogel permits steady drug supply by way of contact lens (2024, November 29)

retrieved 29 November 2024

from https://medicalxpress.com/information/2024-11-3d-hydrogel-enables-drug-delivery.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.