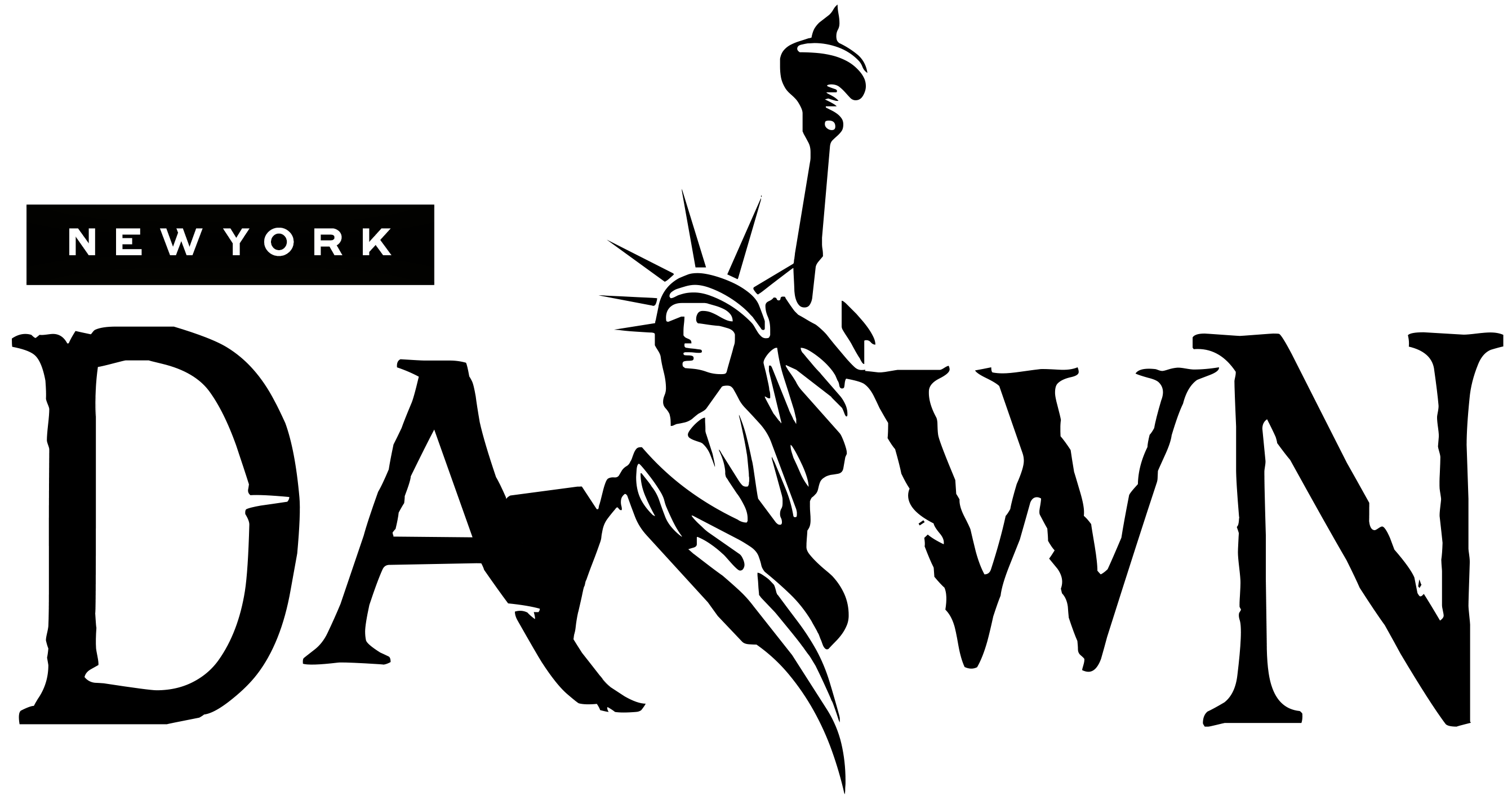

Schematic of the set-up. Credit score: Spectrochimica Acta Half A: Molecular and Biomolecular Spectroscopy (2026). DOI: 10.1016/j.saa.2025.126761

The outbreak of the COVID-19 pandemic demonstrated the necessity to quickly develop, produce and distribute massive portions of recent vaccines. A crew of researchers at Purdue College and Merck & Co. Inc., referred to as Merck Sharp & Dohme Corp. outdoors of the U.S. and Canada, has now launched a brand new analytical instrument that would assist pharmaceutical firms enhance vaccine manufacturing with speedy monitoring and evaluation.

The analysis crew, led by Mohit Verma, affiliate professor of agricultural and organic engineering at Purdue, validated the patent-pending instrument in exams that efficiently measured the standard and amount of repeatedly flowing viral particles.

“The current methods are more time-consuming and offline,” stated Shreya Athalye, a Purdue graduate scholar in agricultural and organic engineering. Samples have to be faraway from the manufacturing line and transferred to an instrument for testing. However the brand new quality-control instrument can function on the manufacturing line, yielding ends in 30 seconds or much less. “Doing it online will save time and money in vaccine production,” she stated.

Athalye, Verma and their co-authors described their new analytical instrument in Spectrochimica Acta Half A: Molecular and Biomolecular Spectroscopy. They disclosed the innovation to the Purdue Innovates Workplace of Expertise Commercialization, which has utilized for a patent to guard the mental property. The examine mixed the experience of specialists in agricultural and organic engineering, biomedical engineering, pc science, mechanical engineering, and supplies science engineering. The Merck co-authors supplied the samples and ensured the examine’s compatibility with industrial operations.

The researchers primarily based their new instrument on Raman spectroscopy, which employs a laser to acquire a pattern’s molecular fingerprint. “It’s nondestructive in nature, and its ability to work with samples that have water makes it ideal for biological samples such as vaccines,” Athalye stated.

In 2022, Athalye co-authored a examine from the labs of Verma and Arezoo Ardekani, professor of mechanical engineering, that utilized Raman spectroscopy and machine studying to measure the focus of viral particles in samples containing measles, mumps and different viruses.

The brand new examine demonstrated the instrument’s effectiveness in detecting particles of the human cytomegalovirus (CMV), a member of the herpes household. Researchers work with virus-like particles of their efforts to develop a CMV vaccine. CMV primarily infects individuals with compromised immune programs, together with those that obtain transplants.

“CMV structure and mode of action make the vaccine development challenging, but many investigational vaccines are being evaluated in clinical trials,” Athalye famous.

“Process analytical technology, or PAT, holds the potential to enable rapid release of biologics,” Verma stated. “We have worked on this collaborative project with the Ardekani lab in mechanical engineering and with the group at Merck to enable PAT using Raman spectroscopy. By demonstrating that we’re able to characterize CMV at industrially relevant concentrations and flow rates, we support easier adoption of this approach in biomanufacturing.”

The analysis crew is unaware of any earlier report a few Raman spectroscopy-based instrument of this kind for detecting CMV particles. This kind of instrument, referred to as course of analytical expertise, provides improved high quality management by repeatedly monitoring the manufacturing course of.

“The point is that we want to analyze the particle as it is being produced,” Athalye stated. And the expertise is versatile sufficient for software to the manufacturing of different vaccine varieties.

In a 2020 examine, Verma and his colleagues used Raman spectroscopy to determine bacterial and fungal contaminants of concern to the pharmaceutical business. In that venture, the crew developed an assay to detect micro organism 10 occasions bigger than viruses and underneath static circumstances. “In this study, we are moving forward with a system that allows monitoring in continuous flow,” Athalye stated.

Additionally, in 2020, Verma and his co-authors assessed the influence of PAT on the manufacture of antibodies that work very like naturally produced human antibodies.

The researchers examined the brand new system underneath quite a lot of move charges, together with the commercial manufacturing move charge and static circumstances. “We wanted to make sure that we were developing a tool that can be transferred to industrial operating conditions,” Athalye stated. This is applicable particularly to steady manufacturing, by which vaccines and different merchandise move nonstop from the manufacturing line.

“Continuous manufacturing is the future. It is environmentally friendly, and it saves money and resources as well,” Athalye stated. “The critical component of continuous manufacturing is developing a robust quality-control tool, or more specifically, a process analytical tool. That’s what drives me to do this research.”

In future work, the crew will exhibit the usage of Raman spectroscopy for different viruses, vaccines and virus-like particles. “We will also be demonstrating the potential of probe-based methods in delivering such results so that they could be integrated into continuous manufacturing unit operations,” Verma stated.

Extra data:

Shreya Milind Athalye et al, Actual-time monitoring of attenuated cytomegalovirus utilizing Raman spectroscopy permits non-destructive characterization throughout move, Spectrochimica Acta Half A: Molecular and Biomolecular Spectroscopy (2026). DOI: 10.1016/j.saa.2025.126761

Supplied by

Purdue College

Quotation:

Gentle-based instrument repeatedly displays vaccine high quality throughout manufacturing (2025, October 28)

retrieved 28 October 2025

from https://medicalxpress.com/information/2025-10-based-tool-vaccine-quality-production.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.