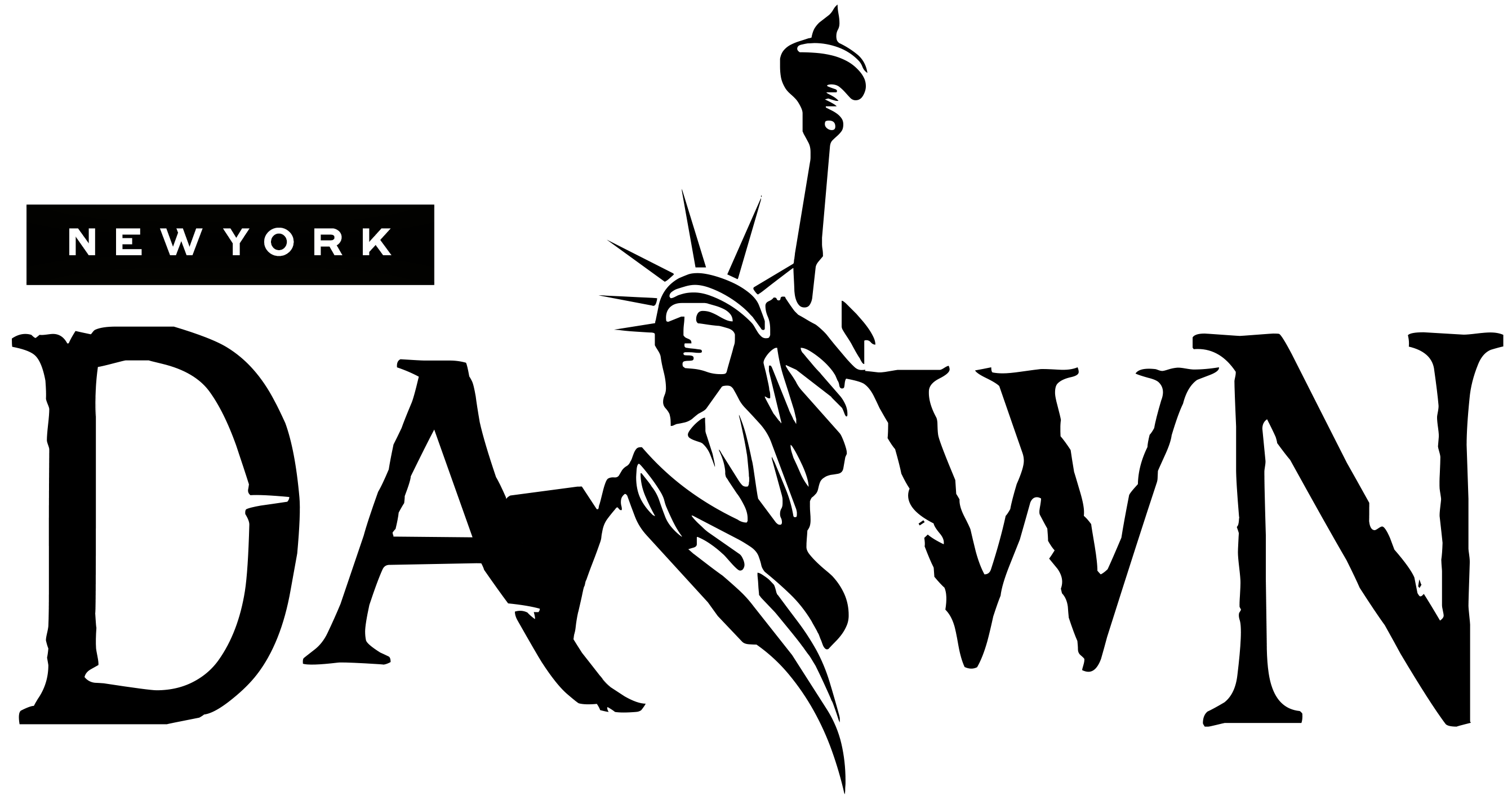

Scanning electron micrograph of a silver-doped porous micro-arc oxide layer on titanium. Credit score: Fraunhofer IFAM

Infectious issues will not be unusual after implant placement. The danger is increased in closely contaminated wounds, that are notably frequent in battle zones reminiscent of Ukraine, the place many bone accidents require remedy. Researchers on the Fraunhofer Institute for Manufacturing Know-how and Superior Supplies IFAM in Bremen have developed a brand new functionalized floor that may be loaded with antibiotics.

Given the heavy burden on Ukraine’s well being care system from quite a few poorly therapeutic fractures, Fraunhofer IFAM determined in 2023 to assist. Past the present scenario within the nation, a private issue was decisive.

“Two of our employees are from Lviv and were involved in the project from the very beginning. They made contact with the UNBROKEN national rehabilitation center in Ukraine, which we are now closely collaborating with to better understand local needs and further develop the technology in a targeted manner,” says Kai Borcherding, Head of Medical Know-how and Life Sciences at Fraunhofer IFAM.

A particular course of creates pores on the implant floor

The researchers are utilizing what is named micro-arc oxidation (MAO) to supply a brand new sort of floor on titanium implants. The steel components are immersed in a conductive liquid—an electrolyte containing silver salts—and uncovered to as much as 300 volts. Inside minutes, excessive‑power plasma discharges type a silver‑doped oxide layer on the fabric, the place focused voltage utility creates pores and incorporates silver nanoparticles. These reservoirs can then take in antibiotics or different energetic substances, very similar to a sponge.

Native antibiotic administration and silver cut back the danger of an infection

The researchers management pore dimension and construction by selecting the electrolyte and the method parameters. That is essential for the loading capability and the length of antibiotic launch.

“Once the MAO layer is complete, the metal parts are immersed in a highly concentrated antibiotic solution. Capillary forces ensure uniform filling of the pores up to the defined capacity with the drug, which is then released in the body by diffusion. After developing the surface and getting our project partners on board, we tested the antibiotic release profile over the desired period. For this purpose, we conducted in vitro tests at the institute,” says Linda Gätjen, Co-Head of Polymer Chemistry and Materials Habits at Fraunhofer IFAM. Throughout lab testing, the researchers had been additionally in a position to present that silver particles improve the antibiotic’s impact.

Osteosynthesis implant for a mandible, outfitted with a porous floor produced by the use of micro-arc oxidation. Credit score: Fraunhofer IFAM

Easy and quick coating course of

The sort of floor remedy is totally new within the discipline of implants: “Right now, there is nothing comparable on the market. Overall, there are only a few solutions for medical devices that rely on antibiotic coatings, and if they do, the production process is much more complex,” Borcherding says.

The easy setup, even underneath troublesome situations, is a significant benefit of the strategy: Basically, solely an influence provide and a cooling gadget for the immersion tub are wanted for the MAO coating course of. This makes the method so easy and cost-effective that it may even be utilized in disaster areas as soon as the know-how has matured additional. As well as, the MAO floor reveals glorious biocompatibility, supporting speedy implant integration.

Advancing the know-how for Ukraine and past

How the brand new coating performs in observe can be examined in Ukraine. The following steps embody preclinical growth of the know-how and scientific trials, which could possibly be carried out on the UNBROKEN nationwide rehabilitation heart in Lviv. The middle is the most important establishment for hospital care of war-disabled folks in Ukraine.

Because the starting of the battle, it has carried out greater than 10,000 operations. The middle is in pressing want of protected implants, which is why UNBROKEN is planning to safe manufacturing capability in the long run. In the meanwhile, nonetheless, the group remains to be searching for companions in Ukraine and Europe to drive the venture ahead and produce prototypes on web site.

The strategy can be attracting curiosity in Germany. As a know-how associate of Fraunhofer IFAM, the corporate KLS Martin has already supplied pattern implants, which the Bremen-based researchers are at the moment engaged on—a primary step towards utility.

Tobias Wolfram, who heads the implant analysis division at KLS Martin, explains, “In addition to the high ethical value of the project, we see great potential in the MAO method for medical engineering, beyond bone implants. We are therefore happy to support the team with our expertise and materials.”

Fraunhofer IFAM can be presenting a human cranium reproduction that includes titanium implants designed to forestall infections on the worldwide commerce present MEDICA, which can be held in Düsseldorf from November 17 to twenty, 2025.

Offered by

Fraunhofer-Gesellschaft

Quotation:

Revolutionary surfaces to quickly load bone implants with antibiotics (2025, November 3)

retrieved 3 November 2025

from https://medicalxpress.com/information/2025-11-surfaces-rapidly-bone-implants-antibiotics.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.